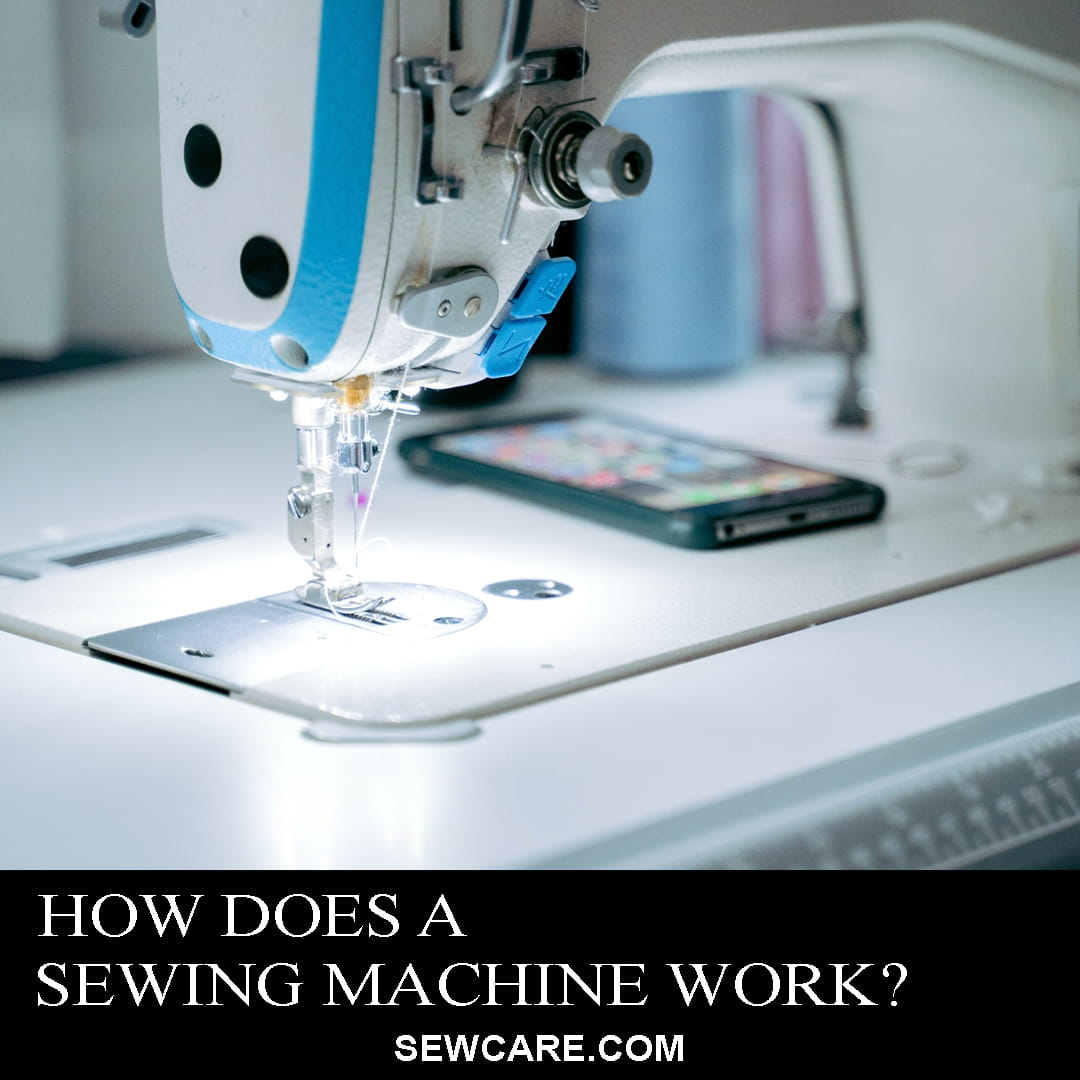

While hand sewing with a needle and thread can be a great way to learn some sewing basics, it can also be time-consuming and frustrating.

There are countless reasons why people invest in a sewing machine. It can save you time, allow you to take on more sewing projects, and afford even inexperienced users the ability to produce professional-level stitches.

Here, we’ll take a closer look at what sewing machines are and how they operate to help you better understand these machines.

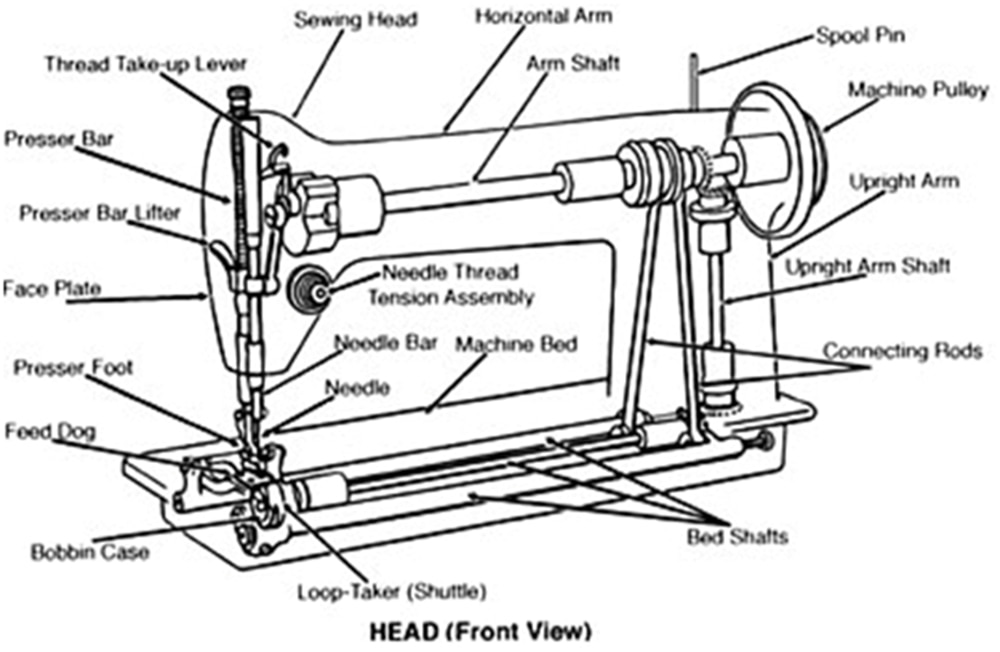

Simple Diagram of a Standard Sewing Machine:

What is a Sewing Machine?

What is a Sewing Machine?

A sewing machine is a mechanical device that allows the operator to produce high-quality stitch work quickly and efficiently.

It sews fabric and materials together using thread. Modern machines pull materials toward the sewing needle and allow the user to glide through their work without the inconvenience that comes from working with needles, thimbles, and other hand sewing tools.

While vintage hand-powered sewing machines are still available, nearly every modern sewing machine is powered by electricity.

The Electric Motor and What it Does

The sewing machine itself is built around an electric motor. Mostare roughly the same size as a vacuum cleaner’s motor.

Durable power cords connect the machine to a nearby power outlet to keep the motor running.

The motor drives three separate mechanisms, which are all timed to work in conjunction with one another. The first twoare a mixture of cams and cranks, which are used to operate the feed system. One pushes upward against the material to hold it in place while the other moves the material forward at an adjustable speed.

These mechanisms essentially work together to pull the materials you’re stitching toward the needle and presser foot. The third mechanism, a crankshaft, makes the sewing needle rise up and down. It also turns the shuttle and hook mechanisms, which are responsible for making the stitch.

Computerized Machines

As technology has advanced, some sewing machine manufacturers have equipped their machines with internal computers. While these computerized sewing machines still follow the basic operating principles of a traditional device, the internal computer gives the user the option to create complex decorative stitches with little effort.

These machines also feature electronic displays that make it easier for the user to make adjustments without having to manually make a correction.

How Does a Sewing Machine Work?

Below, we’ll detail the three main mechanisms within a standard sewing machine before explaining the process that occurs when a sewing machine is making a stitch.

1. The Needle Mechanism

This is the simplest mechanism of the three. Essentially, a drive shaft and crankshaft work together to move the needle upward and downward through the material.

The crank converts rotary motion generated by the electrical motor into the up-and-down motion that’s needed to drive the sewing needle.

2. The Bobbin and Shuttle Mechanism

A crankshaft shorter than the one used to drive the needle downward is needed to create the stitches. As the motor turns the internal gears, thread is unwound from the bobbin and looped to create a stitch.

If you were sewing by hand, you’d drive the needle through the fabric and then loop it to create a stitch. However, with a sewing machine, this entire process is powered by the machine’s electric motor.

3. The Feed-dog Mechanism

The feed-dog mechanism is what allows sewing machines to work quickly and precisely. It pulls the fabric – or “walks” the material – through the machine at a speed that’s consistent with the needle and bobbin mechanisms.

This process, which ensures the stitches are of equal distance, is facilitated bytwo interlinking mechanisms that are driven by the main shaft. The internal mechanisms are synchronized to move the fabric along at a pace that matches the sewing speed.

This synchronization let’s you stitch at a much faster rate than hand sewing and is responsible for maintaining a perfect distance between stitches, allowing even inexperienced sewers to produce professional-level stitch work.

How Does a Sewing Machine Create a Stitch?

The stitching process occurs as follows:Step 1 – The needle starts in the raised position and then moves downward toward the fabric. At this point, it’s leading the thread through the material so a stich can be made. Step 2 – The needle pierces the material and takes the thread with it. Step 3 – The needle begins rising, but leaves a loop of thread behind. The shuttle hook passes through the loop of thread and catches it. Step 4 – The needle continues to rise. Meanwhile, the shuttle hook drags the thread loop downward. Step 5 – The needle has risen to its highest point, which pulls the thread tight. The threads are now locked together and the stitch is pulled tight. The process material is dragged forward so the entire process can repeat and the next stitch can be made. |

What Happens When the Machine’s Timing is Off?

If the hook reaches the thread loop too early or too late, the machine will fail to create a stitch. Also, the thread won’t loop if the fabric isn’t secure against the machine when the needle makes contact.

Stop sewing and consult the manufacturer’s instructions fyou’re worried your machine is experiencing timing issues. Most will explain how you can correct these problems.

How Can You Learn More About the Inner Workings of a Sewing Machine?

If you’re really curious about how your sewing machine works, you can always take off the protective cover – which is designed to be removable for maintenance and cleaning purposes -to see all of the gears, crankshafts, pulleys, and belts that keep your device running.

You’ll also notice how the electric motor and drive belt are attached to power the rest of the device, as well as how everything moves in conjunction with the crankshaft raising and lowering the needle. Just make sure to leave the cover on as much as possible to help protect your sewing machine from damage and debris.

Why Learn How Your Sewing Machine Works?

Not only is it interesting to learn how your sewing machine works, having a basic understanding of the internal mechanisms will help you identify specific issues. Finding these problems before they lead to greater concerns will aid any repairs or maintenance work.

You might also find that your sewing improves once you understand how your machine works. You’ll find it easier to operate the machine because you’ll understand what’s happening when you’re stitching materials together.

If you’re still unsure how a sewing machine operates, take the time to read through the manufacturer’s instruction manual. It’ll be beneficial regardless of your experience, as nobody will understand how your particular machine works like the original manufacturer.

What is a Sewing Machine?

What is a Sewing Machine?